Creating high-quality annotations for automated surface inspection is a critical step in building an effective defect detection system. Built on the Ango Hub platform, iMerit introduces a purpose-built application for manufacturing defect detection with an algorithm-based predictive model for automation, augmented by active annotation and learning with subject matter experts for high accuracy.

Defect Detection AI

Data Annotation Solution with Purpose-built Application for Automated Surface Inspection

Algorithm-based Models

Automatic surface inspection for steel, ball bearings, automotive

stone slabs, and others

Industry Taxonomy

Built from ISO 8501-3:2006 standards for visual assessment of steel and other surface cleanliness

Quick-Start Setup

Start using the solution without algorithms or effortlessly integrate your pre-existing models

Active Learning System

Conducted by subject matter experts to continuously improve defect detection accuracy

Key Benefits

Explore Other Features

Real-time Notifications

- Immediate flagging of defects allowing for quick remediation

- Amend notifications and their schedule with conditional logic and custom sorting options

- A proactive approach to quality control

Edge Case Management

- Flag edge cases and build a repository with customizable errors for specific nuances

- Build a comprehensive picture of the data to understand what you are feeding into the model and measure the dataset quality

- Ensures precision in detection with effective edge case management

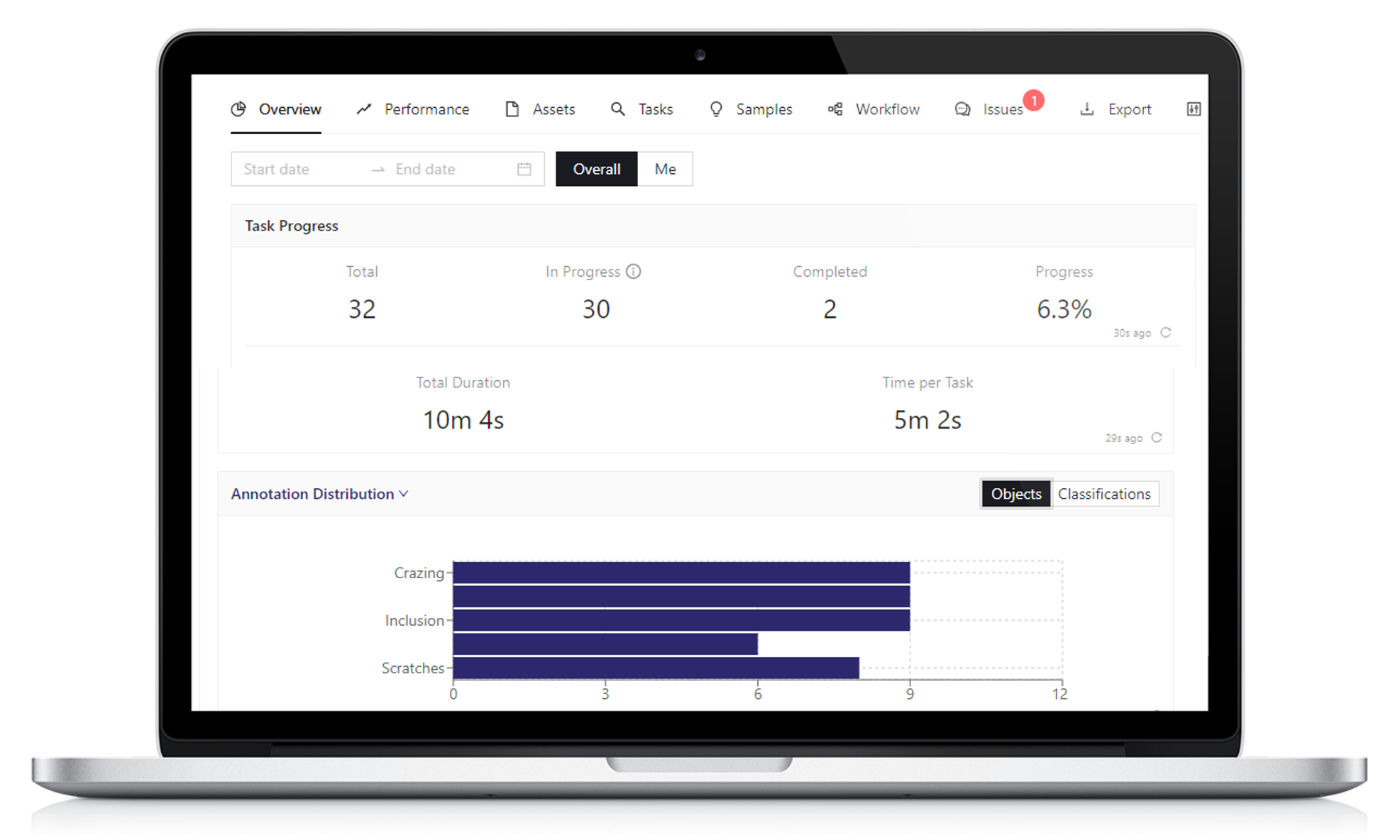

Analytics

- Measure defect severity, defect frequency, defect cost, and defect resolution time

- Seamlessly manage production, profitability, and reputation with our dashboards

- Flexible accessibility for reports and dashboards

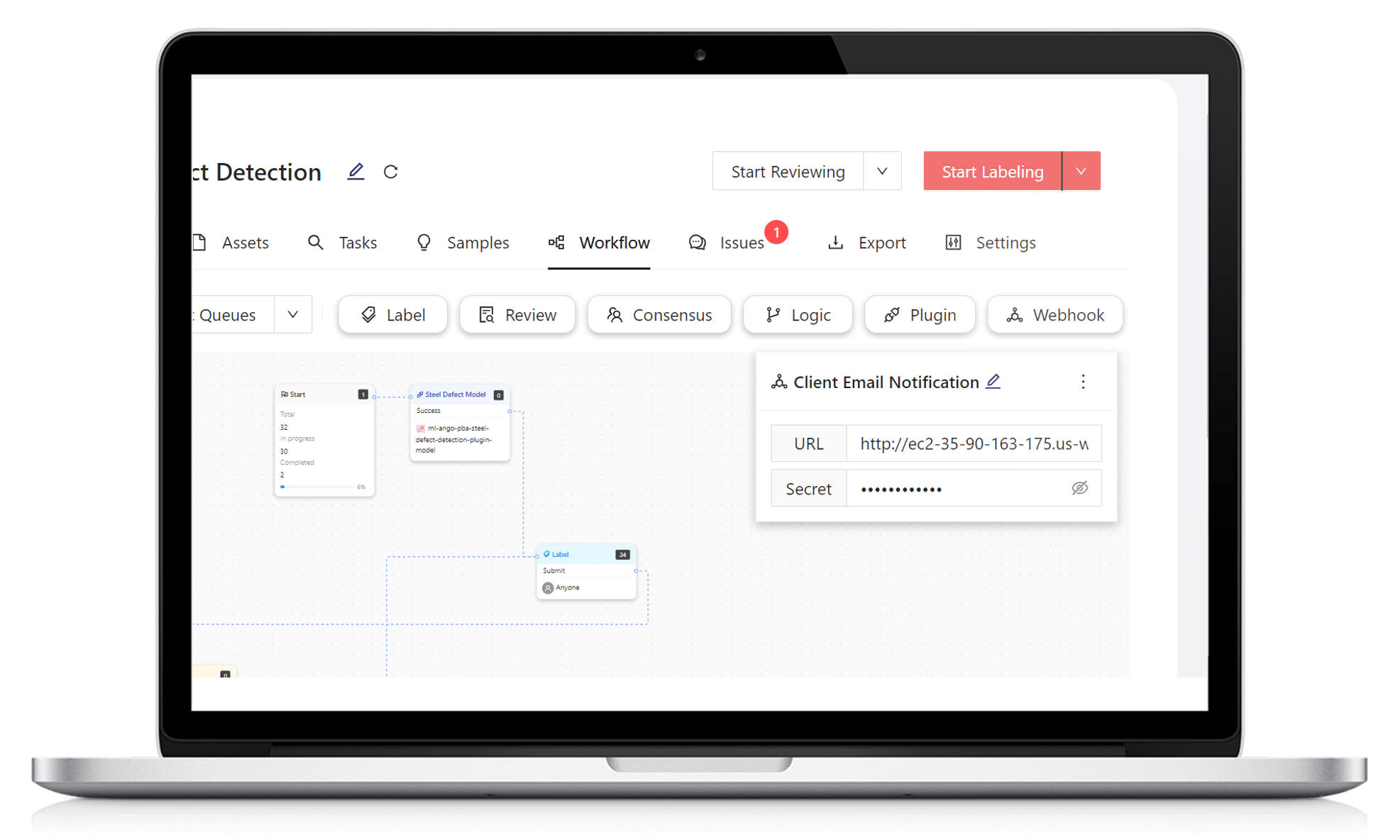

Custom Workflows

Developing a data annotation workflow for a Defect Detection AI or Automatic Surface Inspection model is essential for training and testing the systems. iMerit workflow configuration tool offers unparalleled flexibility, allowing limitless customization and ongoing optimization of scale and efficiency within the data pipeline. Effortlessly build any data labeling process with our end-to-end data annotation platform.

Common Use Cases

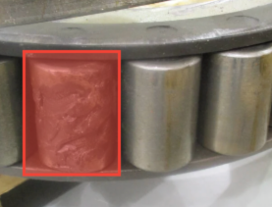

Ball Bearing

Detect defects in ball bearings during the manufacturing process, including surface imperfections, dimensional inaccuracies, cracks, or misalignments.

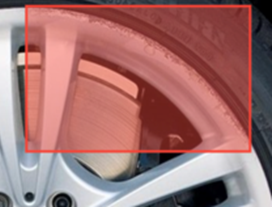

Vehicle Inspection

Detect tire wear, punctures, bulges, bent or cracked rims, damaged spokes, or misalignment in vehicles and automobiles that can affect steering and handling.

Stone & Marble Slabs

Identify surface defects such as cracks, chips, scratches, pits, blemishes, imperfections, and irregularities in stone and marble slabs to ensure high quality.

Get

Started

The need for speed in high-quality data annotation has never been greater. iMerit combines the best of predictive and automated annotation technology with world-class data annotation and subject matter experts to deliver the data you need to get to production, fast.

Contact us