AssetInspection

Turning images and videos of your assets into insights for predictive maintenance

Data-driven Asset Maintenance

Predictive maintenance is a data-driven strategy to optimize and accelerate large-scale production, with skyrocketing adoption across industries like oil & gas, utilities, energy, telecom, etc.

A McKinsey report suggests that predictive asset maintenance can help reduce asset and machine downtime by as much as 50% and increase the life of assets by almost 40%.

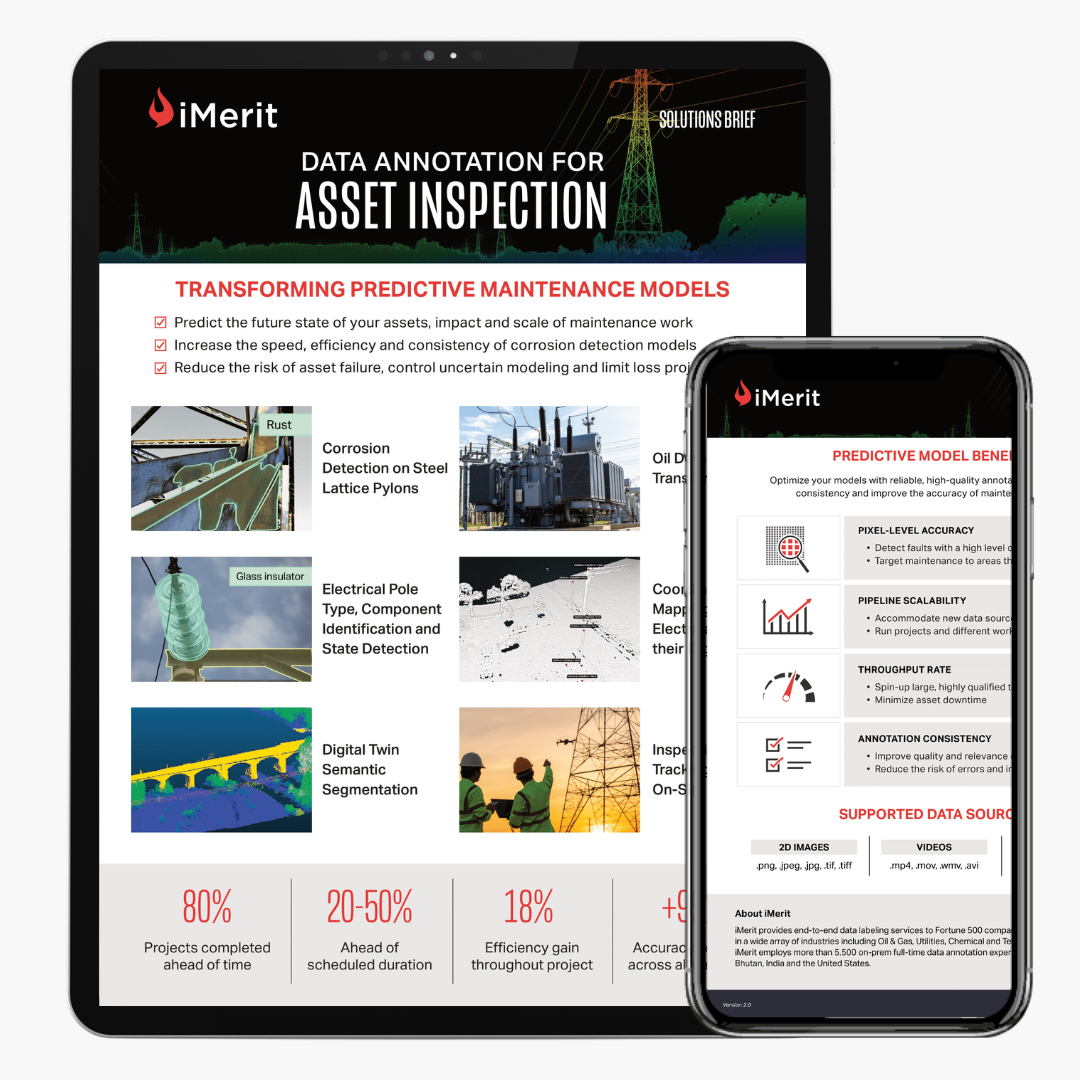

Data Annotation for Asset Inspection

iMerit excels at image and video annotation to help you assess the future state of your assets and the scale of maintenance work to support your predictive maintenance strategy.

With high-quality training datasets curated by expert annotators from our team, we help you improve the efficiency and accuracy of predictive models to reduce the risk of asset failure.

Strengthen Predictive Maintenance Strategies

iMerit has 10+ years of experience working with businesses across numerous industries on their predictive maintenance models. We leverage industry best practices and best-in-class tools to help curate training datasets at scale. Our team will

- Work closely with your MLOps teams to critically evaluate and enhance data annotation guidelines.

- Capture, categorize, and surface edge cases for analyzing asset degradation patterns.

- Implement algorithms to optimize labeling and review efforts.

- Assist you with equipment metadata and other technical information to include in the training dataset for better results.

Contact Us

80

%

Projects completed ahead of time

18

%

Efficiency gain throughout project

95

%

Accuracy achieved across data types

Case Study

Enel Group Partners with iMerit to Analyze their Electrical Distribution Network

With 1.5 million miles of electrical distribution network, Enel Group, a leading European manufacturer and distributor of electricity and gas, was looking to automate manual analysis of the network, as it was error-prone and cumbersome.

The company is working with iMerit to set up and scale data annotation and labeling across multiple data types and scenarios.

Listen to Mario Larcher, Head of Computer Vision at Enel Group, speak about how we helped accelerate their deep learning initiatives.

Common Use Cases

Digital Twin Maintenance

We can help enhance and maintain your Digital Twin to optimize your assets for better safety of your people on the job and a longer life for your machines.

- Asset detection, identification, and classification

- 3D Point Cloud Semantic Segmentation

- Augment point clouds and bring them to life

- Measure asset distances and gauge optimal working states

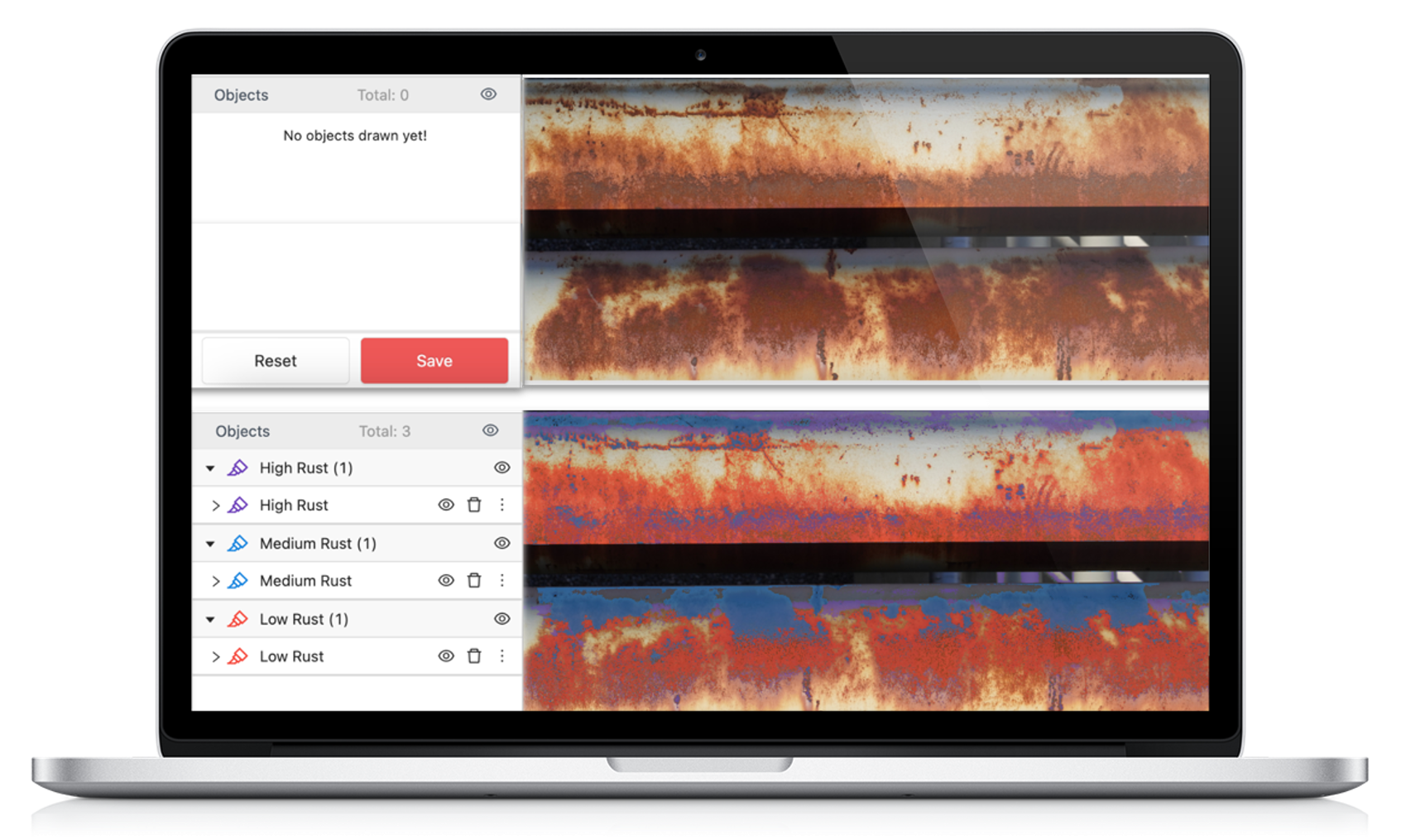

Failure Detection

Our team can capture and detect 2D corrosion, fractures, cracks, and oil/ water presence at the pixel level across multiple degradation labels. We help our clients predict potential failures by:

- Corrosion and oil detection

- Fracture and crack detection

- Identifying roof damages

- Organic material identification and detection

Worker Safety Identification and Tracking

Identify and classify worker safety infractions for actionable intervention and prevent future incidents. With video tracking and interpolation of workers and dangerous scenarios, we can

- Assess worker clothing and compliance with safety standards

- Track worker movements in danger zones

- Monitor harmful scenarios for potential hazards

Download Solution Brief