Accelerating 3D Sensor Fusion

QA Rejection Rate

Throughput

Annotation Time

Discover how iMerit leveraged smart tools and automation to accelerate high-quality 3D sensor fusion annotations for a leading automotive technology company.

Challenge

A global leader in automotive technology faced significant hurdles in processing vast amounts of 3D multi-sensor data crucial for training and validating their advanced perception models. The sheer volume of synchronized LiDAR and camera streams introduced a number of problems:

- Manual annotation of the multi-sensor data was extremely time-consuming

- Traditional manual Quality Assurance (QA) processes created bottlenecks and extended turnaround times

- Scaling operations across diverse environments- from urban to suburban to rural demanded more robust tools and a more efficient workflow

“The significant reduction in our QA rejection rate and the doubling of our monthly output volume are direct reflections of iMerit's commitment to quality and their innovative use of smart tools.”

- Data Operations Lead

Solution

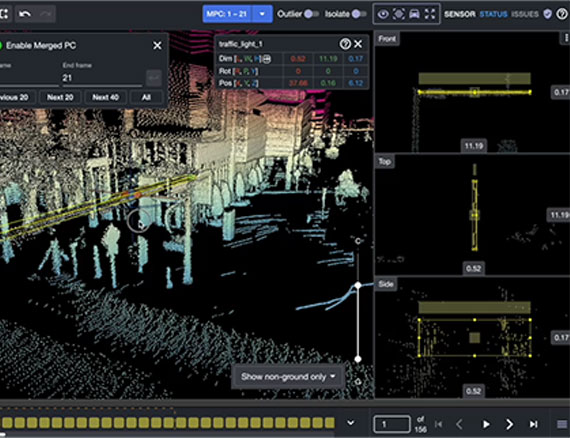

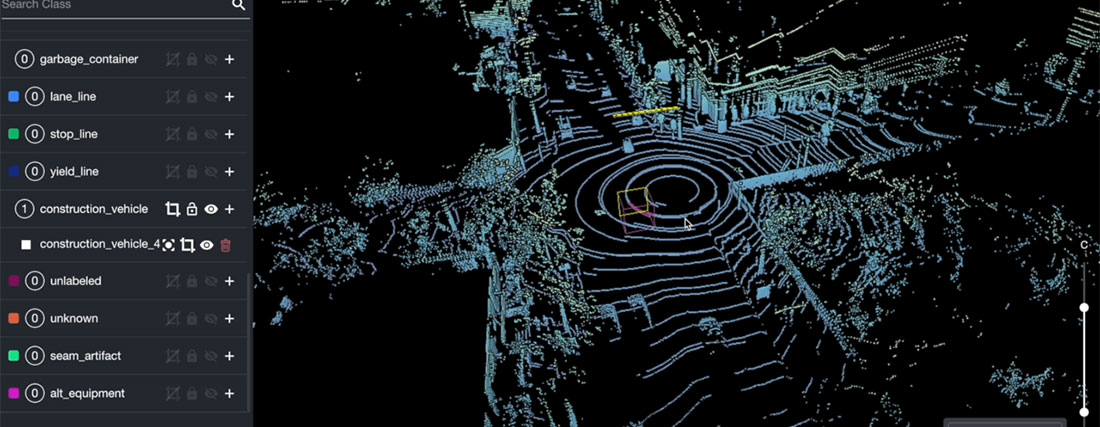

- Smart Annotation Tools: Enabled a multi-modal interface for side-by-side viewing of LiDAR and RGB data, alongside temporal interpolation for object tracking across frames.

- 3D Snapping & Sensor Alignment: Utilized 3D snapping to precisely align bounding boxes with point cloud density and sensor alignment overlays for consistent object visualization across modalities.

- Automation Enhancements: Implemented AI-driven pre-labeling (reducing manual effort by up to 20%) and automated QA rules to detect missing or misaligned objects and JSON output issues.

- Integrated Validation & Feedback: Supported external validation report integration directly into the workflow and incorporated dynamic feedback loops within the annotation UI for continuous corrective learning.

iMerit partnered with the client to implement a comprehensive solution centered on integrating smart annotation tools and advanced automation enhancements. This multi-faceted approach directly addressed the client’s challenges by streamlining the annotation process, improving outputted data quality, and significantly decreasing production times.

The core of the solution lay in iMerit’s deployment of specialized smart annotation tools. These tools provided a multi-modal interface, allowing annotators to simultaneously view and work with synchronized LiDAR and RGB camera data.

Features like temporal interpolation enabled the accurate tracking of objects across consecutive frames, while 3D snapping ensured precise alignment of bounding boxes with point cloud density. Sensor alignment overlays further enhanced consistency by visualizing object alignment across different modalities.

Complementing these tools, iMerit introduced significant automation enhancements. AI models were employed for pre-labeling, reducing manual effort by up to 20%. Automated QA rules were defined to proactively catch missing or misaligned objects and identify any issues in the output JSON.

The workflow also supported external validation reports, integrating third-party checks directly. Crucially, dynamic feedback loops were set up into the annotation UI, fostering continuous learning and rapid corrections for improved output quality.

Result

Key results include:

- 70% decrease in QA rejection rate, a testament to the effectiveness of automated checks and integrated feedback, and a marked improvement in annotation quality.

- 100% increase in monthly output volume, allowing the client to process critical 3D sensor fusion data at an unprecedented scale.

Through the strategic implementation of smart tools and advanced automation, iMerit delivered substantial improvements for the client. The streamlined processes led to a dramatic 40% reduction in overall annotation time, significantly accelerating the client’s go-to-market timelines.

Encouraged by these successes, the client is now poised to expand their collaboration with iMerit, preparing to ramp up an equivalent volume for a second workflow involving similar sensor fusion tasks. A roadmap for further tooling customization and advanced auto-QA triggers based on project-specific failure modes is also planned.